Technology

What is bus bar bending machine

Bus bar bending machine, as a kind of equipment widely used in the power and electrical industry, undertakes the important task of accurately bending busbars according to specific requirements. With the continuous development of modern power systems and electrical equipment, the performance and accuracy of buss bar bending machine are constantly improving to meet increasingly stringent process requirements. This article will comprehensively introduce the basic concepts, working principles, structural characteristics, application fields and development trends of busbar bending machines.

Basic concepts of busbar bending machine

Busbar, as an important part of the power system, is mainly used to transmit and distribute electrical energy. During the installation process of electrical equipment, it is often necessary to bend the busbar to adapt to different installation environments and space layouts. Busbar bending machine, as the name suggests, is a mechanical equipment specially used for bending busbars. It can accurately bend the busbar into the required shape and angle through a series of mechanical actions based on preset parameters.

Working principle of bus bar bending machine

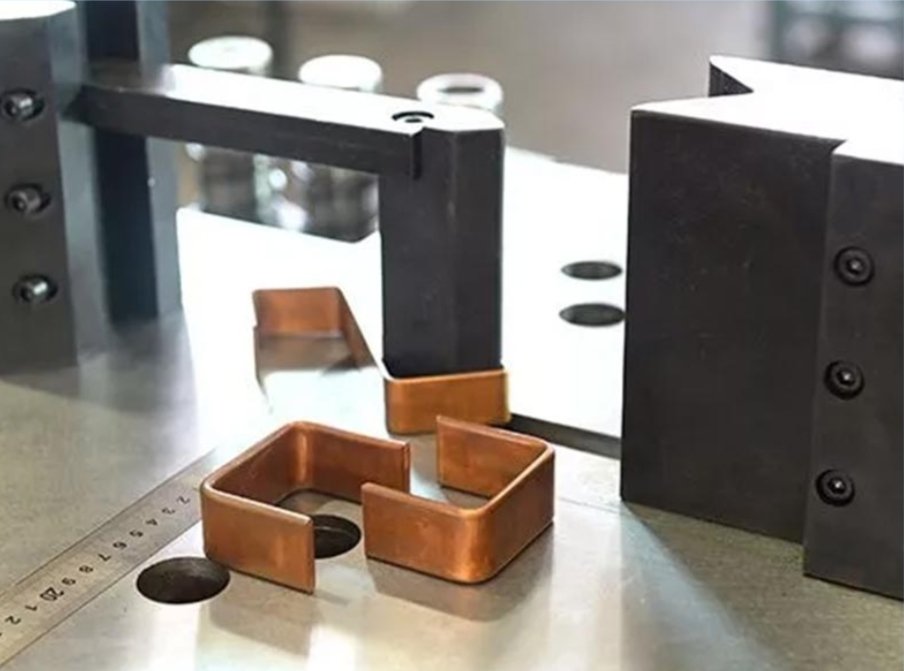

The working principle of the bus bar bending machine mainly relies on its precise mechanical system and control system. During the work process, the busbar to be bent first needs to be placed on the workbench of the machine and fixed in position. Then, according to the bending requirements, set the corresponding bending parameters in the control system, such as bending angle, bending position, etc. Next, start the machine, and the bending machine will drive the bending mold to perform precise bending operations on the busbar through its internal mechanical transmission system according to the set parameters. Finally, after a series of continuous bending actions, the busbar is accurately bent into the preset shape.

If you want to get more professional knowledge about the operation and related performance of the busbar bending machine, you will find it easier to understand the bus bar bending machine information by checking the official website of SunShine Busbar Machine Manufacturing Company at www.busbarmachine.co.

Structural characteristics of buss bar bending machine

Solid frame structure: Buss bar bending machine usually use high-strength metal materials to construct their frames to ensure sufficient stability and rigidity during the bending process, thereby ensuring the accuracy and quality of bending.

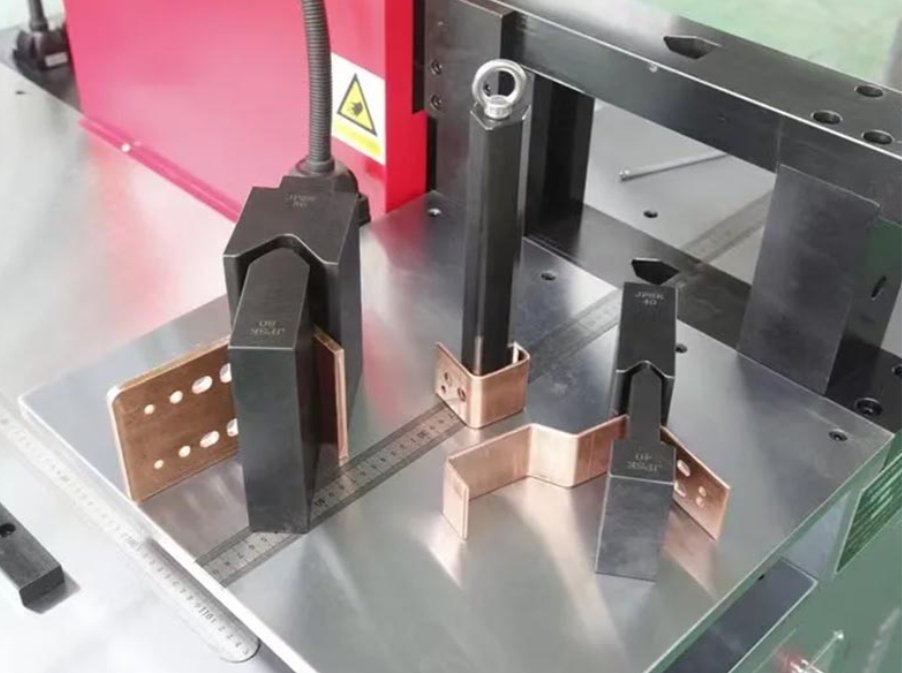

Precision bending mold: The mold is one of the core components of the bus bar bending machine, and its accuracy directly affects the bending effect. High-quality molds can ensure that the busbar is evenly stressed during the bending process and avoid defects such as cracks or deformation.

Advanced control system: Modern busbar bending machine are usually equipped with advanced CNC systems or PLC control systems, which can achieve precise setting and real-time monitoring of bending parameters, greatly improving the convenience of operation and the accuracy of bending.

Versatility: In order to meet the needs of different users, bus bar bending machine are usually designed with multiple bending modes and functions, which can handle busbars of different specifications and materials, achieving a multi-purpose effect.

Application areas of buss bar bending machine

Busbar bending machine are widely used in many fields such as electric power, electrical, new energy, and rail transportation. In the power system, the busbar bending machine is used for busbar installation and renovation projects in substations, distribution rooms and other places; in the electrical equipment manufacturing industry, it is an important equipment on the production line and is used to process various electrical cabinets and switches. Busbar components in cabinets and other products; in addition, in new energy fields, such as wind power, solar power generation and other projects, bus bar bending machine also play an indispensable role.

Development Trend of Busbar Bending Machine

High precision and efficiency: In order to meet the dual requirements of modern electrical equipment for bus bar bending accuracy and efficiency, future busbar bending machine will adopt more advanced transmission mechanisms and control systems to achieve faster and more precise bending operations. .

Intelligence and automation: With the continuous development of artificial intelligence and Internet of Things technology, busbar bending machines will gradually become intelligent and automated. By integrating sensors, actuators, intelligent algorithms and other technical means, future buss bar bending machine will be able to autonomously complete complex bending tasks and provide real-time feedback on working status and data, thereby greatly improving production efficiency and reducing labor costs.

Green environmental protection and energy saving: Against the background of global advocacy of green environmental protection, energy saving and emission reduction, future busbar bending machines will also pay more attention to environmental protection and energy saving design. For example, measures such as adopting low-energy-consumption motors and drive systems and optimizing mechanical structures to reduce material consumption and waste generation will become important considerations in the design of future bending machines.

Modularization and customization: In order to meet the individual needs of different users, busbar bending machine may adopt modular design ideas to facilitate users to flexibly configure and customize according to actual needs. At the same time, bus bar bending machine manufacturers will also provide more complete pre-sales consultation and after-sales services to ensure that users can get the best experience.

Conclusion

As an important piece of equipment in the modern power and electrical industry, the bus bar bending machine’s performance and development trends are directly related to the production efficiency and product quality in related fields. With the continuous advancement of technology and changing market demands, we have reason to believe that future busbar bending machines will become more precise, efficient, intelligent and environmentally friendly, contributing more to the development of the power and electrical industry.

-

Business5 months ago

Business5 months agoSepatuindonesia.com | Best Online Store in Indonesia

-

Technology3 weeks ago

Technology3 weeks agoTop High Paying Affiliate Programs

-

Tech5 months ago

Tech5 months agoAutomating Your Window Treatments: The Advantages of Auto Blinds

-

Tech5 months ago

Tech5 months agoUnleash Your Potential: How Mecha Headsets Improve Productivity and Focus

-

Instagram2 years ago

Instagram2 years agoFree Instagram Follower Without Login

-

Reviews11 months ago

Reviews11 months agoAndroid Laptop vs. Chromebook: Which one is better?

-

Instagram2 years ago

Instagram2 years agoIGTOK – Get Instagram Followers, Likes & Comments

-

Business8 months ago

Business8 months agoFollow These 5 Tips To Avail Personal Loans At Lower Interest Rates