Business

Achieving Optimal Performance and Sustainability in Confectionery Packaging Solutions via Metalized Polyester Film: Environmental Considerations

Metalized Polyester Film Performance and sustainability are needed for confectionery packaging,

Performance and sustainability are needed for confectionery packaging, and metalized polyester film from China Metalized polyester film manufacturers present unique opportunities and challenges. In the growing packaging solutions industry, performance and sustainability must be balanced. This research examines metalized polyester film in candy packaging, where aesthetics, preservation, and environmental impact intersect. Metalized polyester film in candy packaging is reviewed for performance, sustainability, and ecological effects.

Metalized Polyester Film Overview

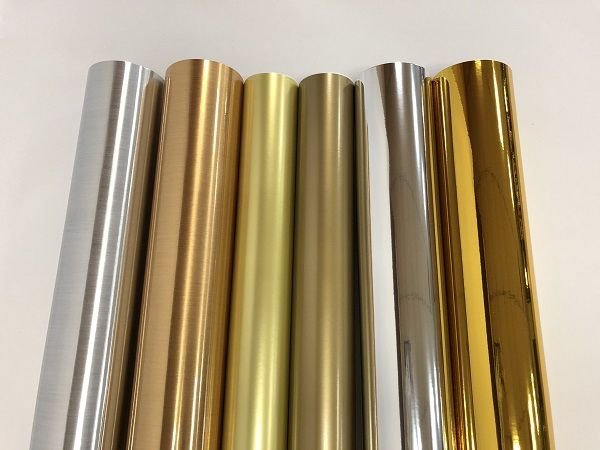

Metallic polyester film is aluminum-coated polyester film used for packaging. Film barrier (moisture, oxygen, and light), printability, and product presentation with a metallic coating are improved. Packaging commonly employs metalized polyester film (polyethylene terephthalate) owing to its unique qualities. A thin aluminum layer covers a polyester film substrate to form this film. Its moisture, oxygen, and light resistance make it suitable for confectionery preservation.

Chocolate, candy, snacks, and other delicacies are typically wrapped with metalized polyester film. It protects delicate sweets from moisture and oxygen while looking lovely, so makers and purchasers like it.

Metalized Polyester Film Performance

1. Barrier Properties:

Metalized polyester film excels in barrier characteristics. The metal covering blocks moisture and oxygen, keeping the confectionery fresh longer. By blocking humidity and oxygen, metalized polyester film prevents staleness and spoiling in confectionery items. This feature is essential for product quality and customer happiness.

2. Printable and attractive:

High-quality printing on metalized polyester film is ideal. This capability allows manufacturers to produce vivid, visually attractive packaging that grabs customers’ attention and communicates brand identity. Metalized polyester film prints well, displaying colorful images and comprehensive product information, improving package marketing and brand communication.

3. Flexibility and Formability:

Polyester film, especially metalized versions, is flexible and may be fashioned into bags, wraps, and sleeves. This flexibility improves package manufacturing and customer convenience.

4. Tear Resistance:

Metallic polyester film is tear-resistant, which is vital in confectionery packaging to avoid tearing and preserve product quality.

5. Appearance:

Metallic film from China Metalized polyester film suppliers improves the look of candy packaging, boosting brand identification and customer perception. Customizing the reflecting surface with colors and decorations gives it a premium appearance and feel.

6. Mechanical Strength:

Polyester film is strong even when metalized, protecting it during handling and shipment. This assures package integrity throughout the supply chain.

Environmental and Sustainability Issues

Metalized polyester film has performance advantages, but its environmental effect raises sustainability concerns:

1. Recyclability:

Metalized polyester film recycling is a significant issue. Metallic content complicates recycling and may reduce its recyclability compared to pure polyester films. Environmental protection requires proper disposal and recycling systems.

2. Resource Intensity:

Metalized polyester film requires a lot of energy, as do aluminum and polyester. Extraction of these materials may cause habitat loss and carbon emissions.

3. Death, dying, and management:

Wasted metalized polyester film, especially in landfills, pollutes. Long-term environmental persistence is achieved by the metal layer, which prevents the biodegradation of film substrates.

4. Alternative Materials and Innovations:

Manufacturing companies are researching new packaging materials and ideas to address environmental issues. These comprise recyclable or biodegradable films, bio-based barriers, and revolutionary coating methods using less non-renewable resources.

Balancing Performance and Sustainability

A comprehensive strategy is needed to reconcile performance and sustainability using metalized polyester film in confectionery packaging:

1. Optimizing Design:

Packaging designers may optimize metalized polyester film constructions for material efficiency and recyclability. Barrier material efficiency and lightweight reduce environmental impact.

2. Lifecycle Assessment:

LCAs of packaging materials estimate environmental consequences from raw material extraction to end-of-life disposal. This information guides sustainable decisions and improvement.

3. Value Chain Collaboration:

Packaging producers, brand owners, recyclers, and legislators must collaborate to innovate and create circular economy solutions for metalized polyester film and other packaging materials.

4. Consumer Education:

Understanding appropriate disposal and the environmental effects of packaging choices helps customers make educated choices and support sustainable packaging projects.

5. Recyclability:

Metalized polyester film is challenging to recycle. The metal layer complicates recycling and requires sophisticated separation and recovery procedures.

6. Death-related disposal:

Metalized polyester film improper disposal pollutes the environment. Landfilling accumulates non-biodegradable garbage, whereas incineration releases toxic compounds into the atmosphere.

7. Resource Intensity:

Metalized polyester film requires a lot of energy and materials, including polyester and aluminum. This challenges the material’s environmental impact.

Balance Performance and Sustainability

Metalized polyester film performance and sustainability are being reconciled:

1. Material Innovation:

Novel solutions are being developed to improve metalized film recycling. Packaging innovations, including water-soluble coatings and metal recovery, seek to promote circularity.

2. Lifecycle Analysis:

Comprehensive lifecycle assessments (LCAs) study metalized polyester film’s environmental effect throughout its lifespan. Identifying improvement potential guides decision-making.

3. Substitute Materials:

To reduce the environmental impact of confectionery packaging, explore materials with similar barrier qualities and excellent recyclability. Industries are exploring biodegradable films and coatings as possible replacements.

Future Innovations and Trends

Future developments and breakthroughs in sustainable candy packaging include:

1. Biology-based films:

Bio-based films made from sustainable resources like plant-based polymers are viable packaging solutions.

2. Technologies for Recycling:

Chemical recycling and depolymerization may improve the recyclability of metalized polyester film and other complicated packaging.

3. Circular Economy Initiatives:

In packaging supply chains, circular economy concepts like design for recyclability and closed-loop recycling reduce waste and enhance resource efficiency. Industry cooperation and circular economy regulations drive sustainable packaging innovation. These programs promote waste reduction and resource efficiency.

4. Legal Environment:

Industry initiatives to reduce packaging waste and extended producer responsibility (EPR) are driven by changing rules.

5. Consumer Awareness:

Increasing consumer knowledge and demand for eco-friendly packaging solutions encourage producers to use sustainable materials. This change emphasizes supply chain openness and accountability.

6. Technological Advances:

Materials science and recycling technologies may improve metalized polyester film’s sustainability. Process improvements and infrastructural investments drive advancement.

Conclusion

Finally, confectionery packaging relies on metalized polyester film for performance and attractiveness. However, its environmental effect requires a systematic strategy to balance performance and sustainability. The confectionery sector may improve packaging sustainability for now and future generations by using innovations, improving design, and collaborating throughout the value chain.

Metalized polyester film improves candy packaging performance and aesthetics, but its environmental effect requires a sustainable strategy. To balance these factors, the value chain must collaborate, innovate, and adapt to customer demands for eco-friendly goods. Emphasizing sustainability without sacrificing performance can help the confectionery packaging business build a more resilient and ecologically friendly future.

Table of Contents

-

Business5 months ago

Business5 months agoSepatuindonesia.com | Best Online Store in Indonesia

-

Technology3 weeks ago

Technology3 weeks agoTop High Paying Affiliate Programs

-

Tech5 months ago

Tech5 months agoAutomating Your Window Treatments: The Advantages of Auto Blinds

-

Tech5 months ago

Tech5 months agoUnleash Your Potential: How Mecha Headsets Improve Productivity and Focus

-

Instagram2 years ago

Instagram2 years agoFree Instagram Follower Without Login

-

Reviews11 months ago

Reviews11 months agoAndroid Laptop vs. Chromebook: Which one is better?

-

Instagram2 years ago

Instagram2 years agoIGTOK – Get Instagram Followers, Likes & Comments

-

Business8 months ago

Business8 months agoFollow These 5 Tips To Avail Personal Loans At Lower Interest Rates