Tech

Why Choose Diaphragm Pumps for Your Needs

Introduction

In the intricate world of fluid dynamics, diaphragm pumps hold a distinguished place. Their unique design and functional prowess have rendered them indispensable across a plethora of industries. This article delves into the myriad reasons why diaphragm pumps are an optimal choice for your pumping requirements.

Overview of Diaphragm Pumps

Definition and Basic Function

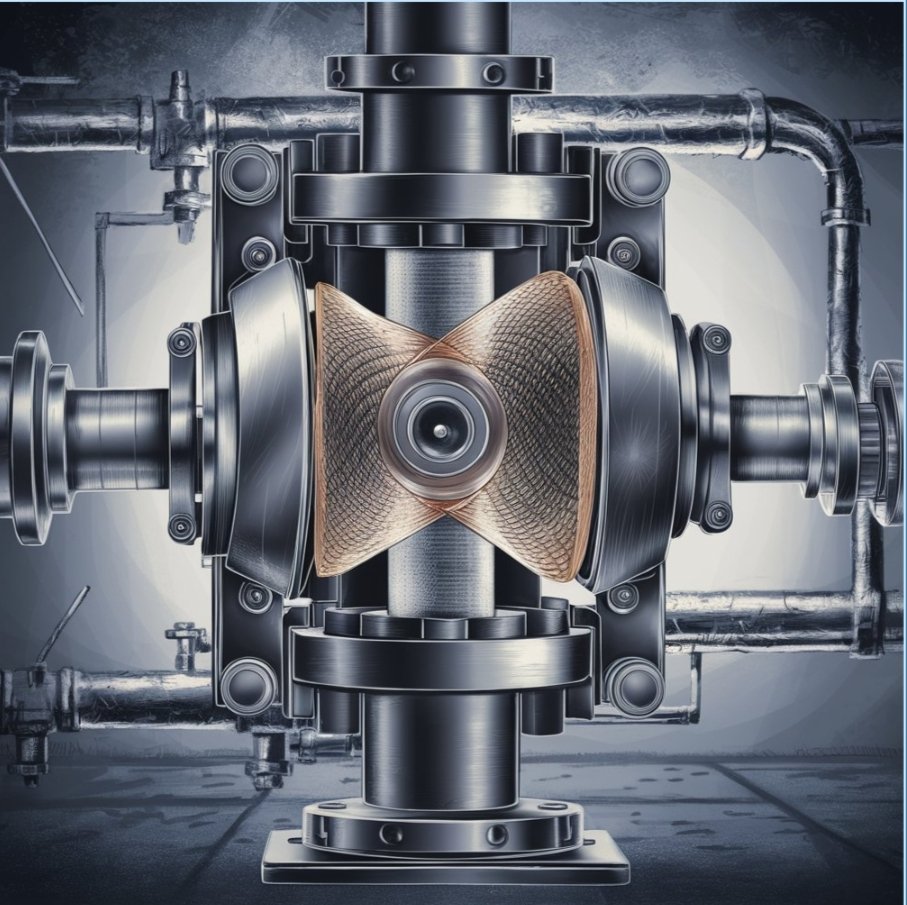

Diaphragm pumps are positive displacement pumps that utilise a combination of reciprocating action and flexible diaphragms to move fluids. These pumps are known for their ability to handle a variety of substances, including viscous, abrasive, and chemically aggressive fluids.

Types of Diaphragm Pumps

Diaphragm pumps can be broadly classified into air-operated diaphragm pumps (AODD) and electric-driven diaphragm pumps. AODD pumps leverage compressed air to drive the diaphragms, while electric-driven pumps utilise electric motors. Each type has its own set of advantages, making them suitable for different applications.

Key Components and Working Mechanism

The primary components of a diaphragm pump include the diaphragm, inlet and outlet valves, and the driving mechanism (air or electric motor). The working mechanism involves the reciprocating motion of the diaphragm, which creates a vacuum to draw fluid into the pump chamber and then expels it through the outlet valve. This simple yet effective mechanism ensures a steady and controlled flow of fluids.

Advantages of Diaphragm Pumps

Versatility Across Industries

One of the most compelling reasons to choose diaphragm pump is their versatility. These pumps are used in industries ranging from chemical processing and water treatment to food and beverage production. Their ability to handle a wide range of fluids makes them a valuable asset in diverse operational environments.

Energy Efficiency and Cost Savings

Diaphragm pumps are renowned for their energy efficiency. Their design minimises energy loss, ensuring that the majority of the input energy is used for fluid movement. This efficiency translates into significant cost savings over time, particularly in large-scale operations where energy costs can be substantial.

Durability and Low Maintenance Requirement

Durability is another hallmark of diaphragm pumps. Constructed from robust materials, these pumps are designed to withstand harsh conditions and rigorous use. Moreover, their simple design means that they have fewer moving parts, which reduces the likelihood of mechanical failure and lowers maintenance requirements.

Applications of Diaphragm Pumps

Use in Chemical Processing

In the chemical industry, diaphragm pumps are prized for their ability to handle corrosive and hazardous fluids safely. Their hermetic sealing prevents leaks and ensures that even the most aggressive chemicals are pumped without risk of contamination or damage to the pump.

Role in Water and Wastewater Treatment

Water and wastewater treatment plants frequently utilise diaphragm pumps due to their reliability and ability to handle a variety of sludge and slurry mixtures. These pumps are crucial for processes such as chemical dosing, sludge handling, and dewatering.

Benefits in Food and Beverage Production

The food and beverage industry benefits immensely from diaphragm pumps’ sanitary design. These pumps can handle viscous food products and sensitive beverages without compromising on hygiene standards. Their gentle pumping action preserves the integrity of delicate food items.

Applications in Oil and Gas Industry

In the oil and gas sector, diaphragm pumps are used for transferring and injecting a wide range of fluids, including crude oil, drilling mud, and chemicals. Their robust construction and ability to operate in explosive environments make them an ideal choice for this demanding industry.

Comparing Diaphragm Pumps to Other Pump Types

Diaphragm Pumps vs. Centrifugal Pumps

While centrifugal pumps are excellent for high-flow, low-viscosity fluids, diaphragm pumps excel in handling viscous, abrasive, and corrosive substances. Diaphragm pumps also offer better control over flow rate and pressure.

Diaphragm Pumps vs. Peristaltic Pumps

Both diaphragm and peristaltic pumps are suitable for handling sensitive fluids. However, diaphragm pump brisbane typically offer higher pressure capabilities and better handling of abrasive fluids compared to peristaltic pumps.

Diaphragm Pumps vs. Gear Pumps

Gear pumps are effective for high-pressure applications but can struggle with shear-sensitive fluids. Diaphragm pumps, on the other hand, are gentle on shear-sensitive fluids and can handle a broader range of fluid types.

Selecting the Right Diaphragm Pump

Factors to Consider (Flow Rate, Pressure, etc.)

When selecting a diaphragm pump, consider factors such as flow rate, pressure requirements, and the nature of the fluid being pumped. Matching these parameters to your operational needs ensures optimal performance.

Material Compatibility with Fluids

The materials used in the pump construction must be compatible with the fluids being handled. This consideration is crucial to prevent corrosion and ensure longevity.

Environmental and Operational Conditions

Assess the environmental conditions in which the pump will operate, including temperature, humidity, and exposure to chemicals. Ensure the pump’s design is suited to these conditions to avoid operational issues.

Installation and Maintenance Tips

Proper Installation Procedures

Proper installation is critical for the optimal functioning of diaphragm pumps. Follow manufacturer guidelines meticulously, ensuring that the pump is securely mounted and all connections are correctly made.

Routine Maintenance Practices

Regular maintenance, including checking for wear and tear and replacing worn-out parts, can significantly extend the lifespan of diaphragm pumps. Scheduled inspections and timely interventions prevent major breakdowns.

Troubleshooting Common Issues

Familiarise yourself with common issues such as diaphragm rupture, valve blockages, and air supply problems. Understanding these issues and their solutions can minimise downtime and maintain operational efficiency.

Innovations and Future Trends in Diaphragm Pumps

Advances in Pump Technology

Ongoing advancements in pump technology are enhancing the performance and efficiency of diaphragm pumps. Innovations such as smart pump controls and improved diaphragm materials are setting new standards in the industry.

Emerging Materials and Designs

The development of new materials and design improvements is making diaphragm pumps more robust and versatile. Emerging materials offer better chemical resistance and durability, while design enhancements improve efficiency and ease of maintenance.

Predictions for Industry Growth

The demand for diaphragm pumps is expected to grow, driven by increasing industrialisation and the need for efficient fluid handling solutions. Innovations and advancements in pump technology will continue to fuel this growth.

Conclusion

Recap of Key Points

Diaphragm pumps offer numerous advantages, including versatility, energy efficiency, and low maintenance requirements. Their applications span across various industries, making them a valuable asset for diverse operations.

Encouragement to Consider Diaphragm Pumps

Given their benefits and wide range of applications, diaphragm pumps are an excellent choice for many fluid handling needs. Investing in a quality diaphragm pump can lead to improved efficiency and cost savings.

Call to Action

Contact Information for Expert Advice

For expert advice on selecting the right diaphragm pump for your needs, contact our team of specialists. We are here to help you find the best solution for your specific requirements.

Links to Further Resources and Reading

Explore our comprehensive resources for more detailed information on diaphragm pumps. Our guides and articles provide in-depth insights to help you make informed decisions.

Conclusion

Recap of Key Points

Diaphragm pumps offer numerous advantages, including versatility, energy efficiency, and low maintenance requirements. Their applications span across various industries, making them a valuable asset for diverse operations.

Encouragement to Consider Diaphragm Pumps

Given their benefits and wide range of applications, diaphragm pumps are an excellent choice for many fluid handling needs. Investing in a quality diaphragm pump can lead to improved efficiency and cost savings.

Call to Action

Contact Information for Expert Advice

For expert advice on selecting the right diaphragm pump for your needs, contact our team of specialists. We are here to help you find the best solution for your specific requirements.

Links to Further Resources and Reading

Explore our comprehensive resources for more detailed information on diaphragm pumps. Our guides and articles provide in-depth insights to help you make informed decisions.

-

Tech1 year ago

Tech1 year agoHow to Use a Temporary Number for WhatsApp

-

Business2 years ago

Business2 years agoSepatuindonesia.com | Best Online Store in Indonesia

-

Social Media2 years ago

Social Media2 years agoThe Best Methods to Download TikTok Videos Using SnapTik

-

Technology2 years ago

Technology2 years agoTop High Paying Affiliate Programs

-

Tech12 months ago

Tech12 months agoUnderstanding thejavasea.me Leaks Aio-TLP: A Comprehensive Guide

-

FOOD1 year ago

FOOD1 year agoHow to Identify Pure Desi Ghee? Ultimate Guidelines for Purchasing Authentic Ghee Online

-

Instagram3 years ago

Instagram3 years agoFree Instagram Auto Follower Without Login

-

Instagram3 years ago

Instagram3 years agoFree Instagram Follower Without Login