Business

Sheet Metal Bending Calculation for Different Design Factors

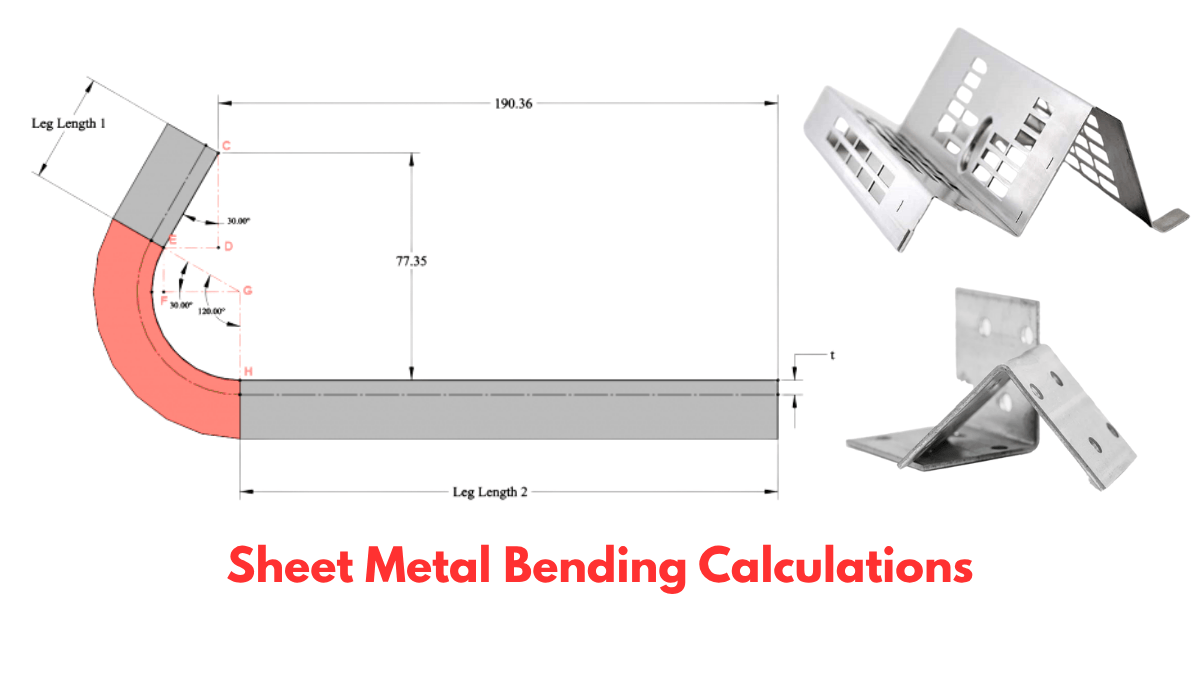

Metal bending calculations

An optimal sheet metal design is crucial for the manufacturability and quality of bent parts. It is essential for structural integrity, strength, and precision. But, do you know how you can make a perfect engineering design for metal bending? Well, you need to calculate the design variables correctly.

This article will discuss sheet metal bending calculations for design consideration, including bend radius, bend allowance, bend deduction, outside setback, k-factor, and springback.

Sheet Metal Bending and Design Considerations

Sheet metal bending involves the use of a die and press setup to bend the sheet into the intended curvature or angle. It can also produce complex shapes via multiple bends and twists. The process starts with the creation of a 2D/3D design that outlines dimensions, bent position, bend radii, and other variables.

Here are the key factors that need to be calculated during design:

- Bend Radius

- Bend Allowance

- Outside Setback

- Bend Deduction

- K Factor

- Springback

Let’s elaborate on these factors and their calculation.

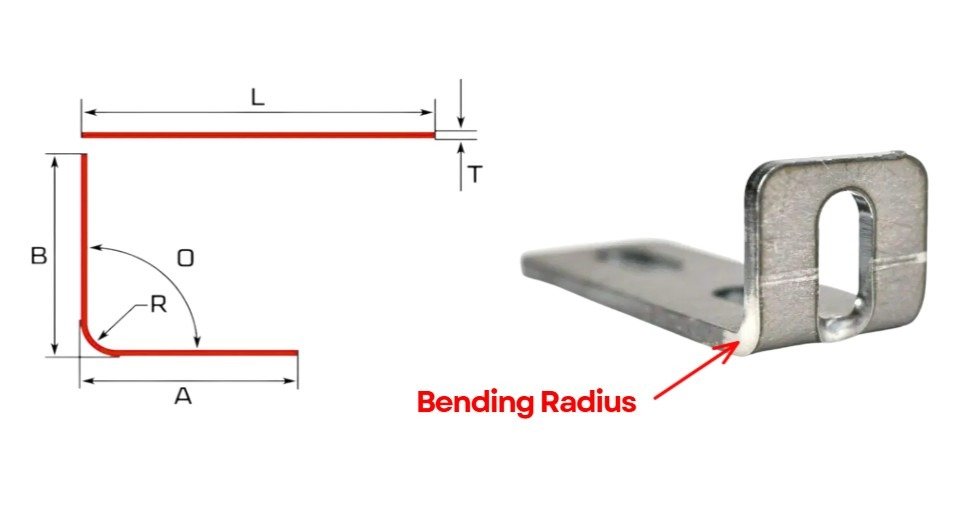

Bend Radius Calculation

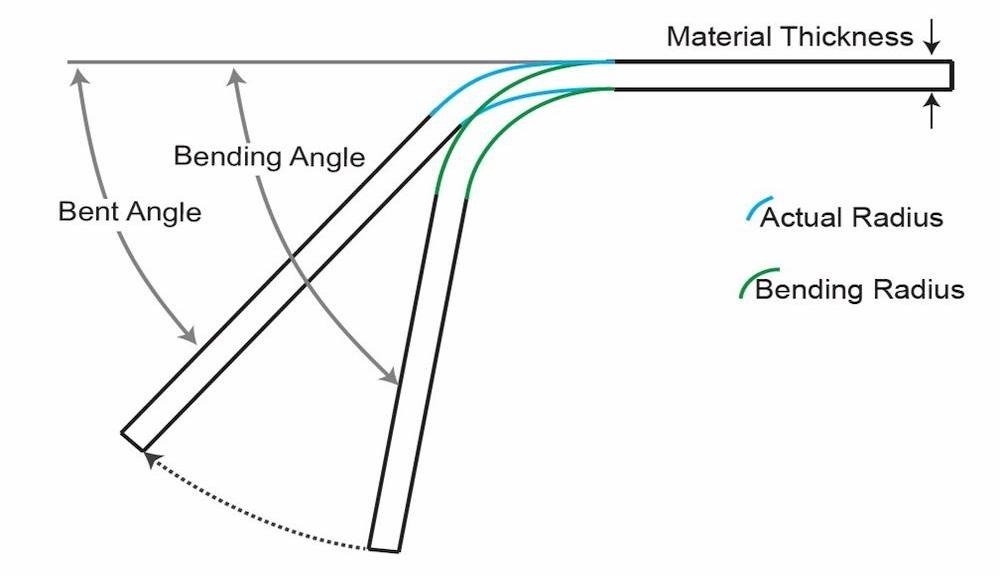

Bend radius diagram

In simple terms, bend radius refers to the curvature radius of the bend, which is measured from the inside surface of the bent sheet to the centre of curvature. When designing, it is essential to know the safe limit of the bending radius. Otherwise, it might occur cracks along the bend line.

A standard practice for minimum bend radius is that it should be at least equal to the sheet thickness.

The bending formula for sheet metal parts is given below.

Minimum bending radius(r) ≤ sheet thickness (t).

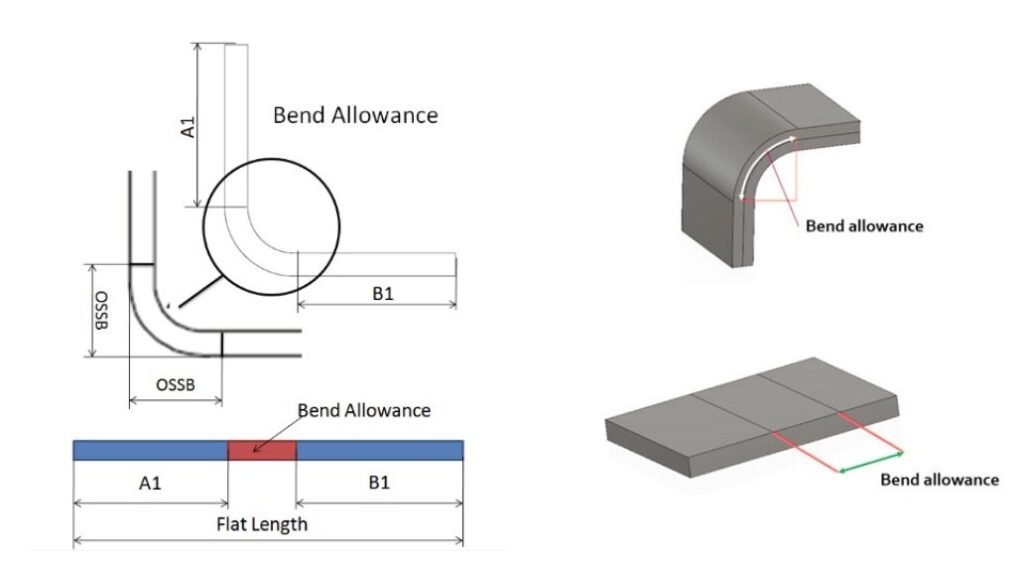

Bend Allowance Calculation

Bend allowance diagram

Bend allowance refers to the length of the bent arc in the neutral axis. So, it is the section of the sheet that will actually go through the forming stress. Designers calculate the bend allowance and add it to the total flat length for the required shape.

Consequently, the bend allowance calculation is essential to compensate for the stretching of the outer surface that occurs while applying the forming force.

You can use the given bending allowance formula for calculation.

BA= [πA(R+KT)]/180

Where,

A=Bent angle ( θ°)

R = Inside bend radius

K= K-factor (a pre-defined value)

T= Thickness of sheet metal

Alternatively, you can use the sheet metal bend radius calculator available online, which is a digital tool that calculates the bend radius based on your inputs, such as thickness, k-factor, and bend angle.

Bend Deduction Calculation

bend deduction diagram

Bend deduction is another crucial calculation in sheet metal bending. It corrects the flat length by compensating the material compression that occurs at the inner section during bending. When you subtract the bend deduction from the two flange lengths, you get the total flat length of the sheet.

It is related to the outside setback and calculated with the formula given below.

BD=2× Outside Setback (OSSB)− Bend Allowance (BA)

Outside Setback

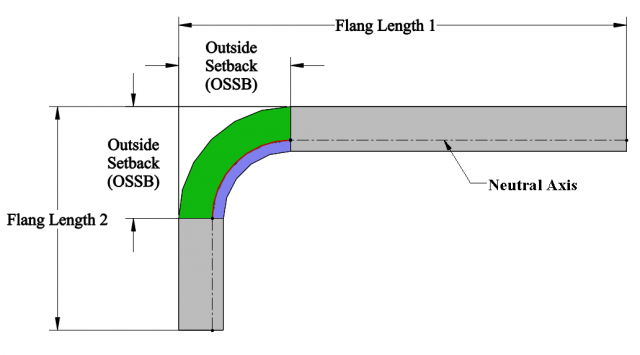

Bending outside setback

Bending outside setback refers to the distance from the apex of the outside bend to the bend tangent line. For instance, setback is equal to the outer bend radius in the 90 degree bend calculation.

The setback calculation determines the outward extension due to bend formation. Consequently, it is essential to locate different features with respect to the bending line.

You can use the given formula to calculate the outside setback.

OSSB= Tan(θ/2) x (R+T)

Where,

θ°= Bend angle

R= Inside bend radius

T= Sheet thickness

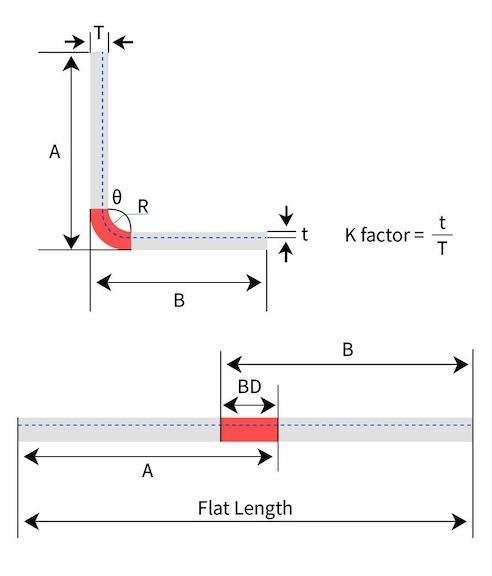

K Factor Calculation

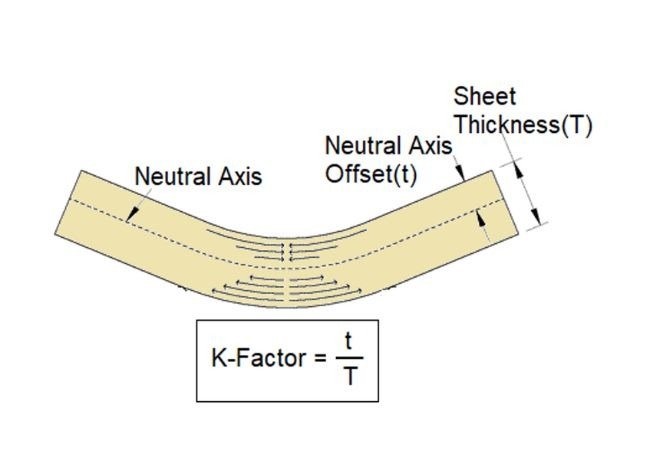

K factor in sheet metal bending

The K-factor is a dimensionless variable that defines the position of the neutral axis and the sheet thickness. It is calculated by dividing the distance from the neutral axis to the inner bend surface by the sheet thickness.

K= Distance between inner bend surface to neutral axis (D)/Sheet thickness (T)

Moreover, designers can directly use the k-factor values from industry standard charts. It helps to control bend allowance, bend reduction, and design variables.

Springback Calculation

Sheet metal springback

Springback is related to the material’s elasticity, which is the tendency of the material to return to its original position after mechanical stress is released.

When the press brake returns after applying force to the sheet metal against the die, the sheet tends to return to its initial flat position, causing deviation in the desired bent angle. Therefore, the designer must consider the springback to achieve accurate bend angles.

The springback calculation formula is given below.

Springback= Bend angle under load ( θformed) – Angle after unloading ( θfinal)

Conclusion

Right calculations of bending radius, allowance, deduction, springback, outside setback, and other variables are crucial while preparing sheet metal designs. These calculations ensure the manufacturability (DFM), precision, and structural integrity of the fabricated parts. Furthermore, it is also essential to ensure your sheet metal bending service has extensive tooling capabilities and advanced equipment.

-

Tech1 year ago

Tech1 year agoHow to Use a Temporary Number for WhatsApp

-

Business2 years ago

Business2 years agoSepatuindonesia.com | Best Online Store in Indonesia

-

Social Media2 years ago

Social Media2 years agoThe Best Methods to Download TikTok Videos Using SnapTik

-

Technology2 years ago

Technology2 years agoTop High Paying Affiliate Programs

-

Tech12 months ago

Tech12 months agoUnderstanding thejavasea.me Leaks Aio-TLP: A Comprehensive Guide

-

FOOD1 year ago

FOOD1 year agoHow to Identify Pure Desi Ghee? Ultimate Guidelines for Purchasing Authentic Ghee Online

-

Instagram3 years ago

Instagram3 years agoFree Instagram Auto Follower Without Login

-

Instagram3 years ago

Instagram3 years agoFree Instagram Follower Without Login