Technology

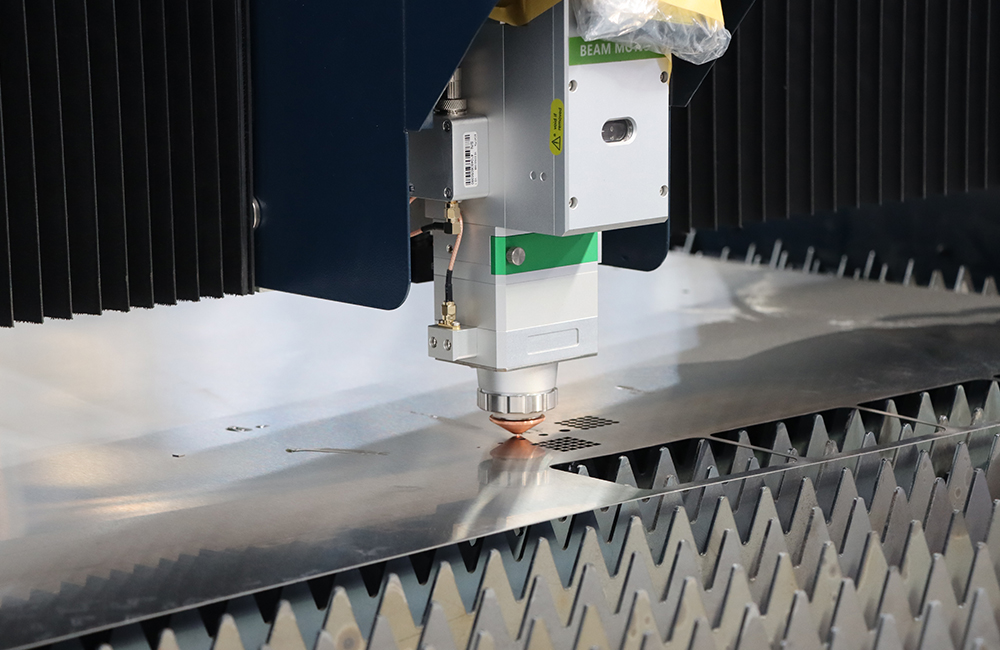

YIHAI Laser Cutter Winter & Daily Maintenance Guide: Freeze Protection, Dust Control & Voltage Stabilization

Essential maintenance guide for cnc fiber laser cutting machine owners facing winter challenges, dust contamination, and voltage fluctuations. Learn proven strategies from real-world case studies in Canada, Australia, and Africa.

Introduction: When Your Laser Cutter’s Environment Becomes Its Greatest Enemy

It’s 3 AM in a Canadian winter, and inside an unheated manufacturing facility, a laser cutter’s cooling system quietly approaches a crisis point. Meanwhile, in the Australian Outback, another machine suddenly halts production as voltage spikes wreak havoc on its sensitive electronics. Across the world in South Africa, dust accumulation threatens to silently destroy a power supply.

These aren’t hypothetical scenarios—they’re real challenges faced by laser cutter operators worldwide. What connects them is that they’re all preventable with proper maintenance practices. This comprehensive guide draws from actual case studies to provide actionable solutions for the three most common—and costly—laser cutter maintenance challenges.

The Canadian Winter Crisis: Preventing Laser Cutter Freeze Damage to Cooling Systems

The Problem: When Cold Weather Turns Deadly

In Alberta, Canada, a manufacturing facility manager arrived at work to discover their $180,00 laser cutter had suffered catastrophic failure overnight. The temperature had plummeted to -25°C, and despite the machine being powered off, the residual water in the cooling system had frozen, expanding and cracking both the laser tube and several critical hoses.

“This wasn’t just inconvenient—it was a $20,00 repair that shut down our primary production line for two weeks,” the manager recalled. “We assumed since the machine was off, it was safe. We were wrong.”

The Science of Freeze Damage

Water expands by approximately 9% when it freezes. In a laser cutter’s cooling system, this expansion creates tremendous pressure that can:

Crack laser tubes and cooling plates

Split PVC and rubber hoses

Damage pump housings and seals

Compromise heat exchanger integrity

The Solution: A Two-Pronged Defense Strategy

1. Proper Antifreeze Implementation

| Antifreeze Type | Mixing Ratio | Protection Level | Change Frequency |

| Ethylene Glycol (Standard) | 30% – 40% | Down to -20°C | Annual |

| Propylene Glycol (Food-Safe) | 40% – 50% | Down to -25°C | Annual |

| Industrial Laser Antifreeze | 30% – 50% | Down to -30°C | Per Manufacturer |

Antifreeze Guidelines for Laser Cooling Systems

Important Note: Never use automotive antifreeze, as it can damage laser system components and reduce cooling efficiency.

2.Low-Temperature Circulation Mode

Most modern laser cutters include an automatic anti-freeze protection setting that:

∙Maintains water circulation during cold periods

∙Activates heating elements when temperatures drop

∙Monitors system temperature continuously

∙Consumes minimal power while providing critical protection

Action Steps for Winter Protection:

- Test current coolant mixture with a refractometer

- Drain and replace with appropriate antifreeze mixture

- Enable low-temperature circulation in machine settings

- Verify functionality with overnight monitoring

What impact will unstable voltage have on the laser cutting machine?

The Reality of Remote Manufacturing

At a mining support facility in Western Australia, the operations manager described their power situation as “like trying to drink from a firehose.” Voltage readings would swing from 360V to 420V on a supposed 400V system, causing frequent machine shutdowns and alarming error messages.

“We lost $8,000 in ruined materials and production time before we realized the common denominator was our unstable power supply,” the manager explained. “The grid out here wasn’t built for precision manufacturing equipment.”

How Voltage Flucturations Damage Laser Systems

Unstable power doesn’t just cause shutdowns—it creates cumulative damage:

∙Laser Source: Power fluctuations reduce diode lifespan and cause inconsistent output

∙Stepper Motors: Under – voltage causes overheating; over – voltage damages drivers

∙Controller Electronics: Spikes fry circuit boards and corrupt memory

∙Power Supplies: Repeated stress causes premature failure

The Automatic Voltage Regulator (AVR) Solution

An industrial – grade AVR acts as a “power conditioner” that:

∙Maintains output voltage within ±5% regardless of input variations

∙Filters out spikes and electrical noise

∙Provides surge protection during lightning strikes or grid switching

∙Compensates for brownouts and over – voltage conditions

AVR Selection Criteria:

| Machine Power | Minimum AVR Capacity | Response Time | Voltage Range |

| 3-5 kW Laser | 15 kVA | <1 Second | 300V-460V |

| 6-8 kW Laser | 25 kVA | <1 Second | 300V-460V |

| 9-12 kW Laser | 35 kVA | <0.5 Seconds | 300V-460V |

AVR Sizing Guidelines for Laser Cutters

Implementation Process:

①Conduct a week-long power quality analysis

②Select appropriately sized AVR with sufficient capacity

③Install with proper electrical safety measures

④Monitor output voltage to verify stabilization

Results from the Australian Facility:

①Machine faults reduced from weekly to zero

②Laser source service alerts eliminated

③Product quality consistency improved by 30%

④ROI achieved in 4 months through prevented downtime

The African Dust Management Dilemma: Protecting Electrical Components

The Invisible Threat in Plain Sight

A manufacturing plant in South Africa discovered their CNC fiber laser cutting machine was accumulating nearly 2kg of dust annually inside electrical enclosures. The fine, abrasive dust was causing overheating and creating conductive paths between components.

“We clean our floors daily, but never thought about the inside of our electrical cabinets,” the maintenance supervisor admitted. “The dust was so fine it looked like a light coating, but under magnification, we saw it was building up between every pin and connector.”

Why Dust is More Than Just Dirt

Industrial dust creates multiple failure mechanisms:

∙Insulation: Acts as a thermal blanket, causing components to overheat

∙Abrasion: Wears down moving parts and connector surfaces

∙Conductivity: Can create unintended electrical paths

∙Corrosion: Holds moisture and promotes oxidation

∙Contamination: Interferes with optical sensors and cooling fans

Safe Cleaning Protocols for Electrical Enclosures

Required Equipment:

∙ESD-safe vacuum cleaner with HEPA filter

∙Low-pressure compressed air (below 50 PSI)

∙Anti-static brushes and cleaning tools

∙Personal protective equipment (safety glasses, mask)

Step-by-Step Cleaning Procedure:

1.Power Down & Lock Out: Complete electrical isolation is non-negotiable

2.Initial Vacuuming: Remove bulk dust with ESD-safe vacuum

3.Detailed Cleaning: Use compressed air and brushes for intricate areas

4.Inspection: Check for signs of overheating or damage

5.Verification: Ensure complete reassembly before power-up

Maintenance Frequency Guidelines:

| Environment | Visual Inspection | Light Cleaning | Thorough Cleaning |

| Clean Workshop | Monthly | Quarterly | Annual |

| Moderate Dust | Weekly | Monthly | Quarterly |

| Heavy Contamination | Daily | Weekly | Monthly |

Electrical Cabinet Cleaning Schedule Based on Environment

Critical Safety Reminders:

Never use high-pressure air that can force dust deeper into components

Always use ESD-safe equipment to prevent static damage

Document each cleaning for maintenance records

Train multiple staff members on proper procedures

Building Your Comprehensive Maintenance Schedule

Daily Maintenance (5-10 Minutes)

Check coolant levels and temperature

Verify air pressure and filtration

Clean exterior surfaces

Review error logs

Weekly Tasks (15-20 Minutes)

Inspect lens and mirrors

Check for loose connections

Verify exhaust system operation

Clean work area thoroughly

Monthly Maintenance (30-60 Minutes)

Complete optical path cleaning

Inspect electrical cabinets for dust

Verify water quality and chemistry

Test safety interlocks

Seasonal Preparation

Winter: Antifreeze verification, pipe insulation

Summer: Cooling system efficiency check, ambient temperature monitoring

High-Dust Seasons: Increased filtration attention, more frequent cleaning

The Cost of Neglect vs. The Value of Prevention

Real-World Cost Comparison:

| Maintenance Issue | Preventive Cost | Repair Cost | Downtime Impact |

| Freeze Damage | $150 (Antifreeze) | $3,000-$15,000 | 1-3 Weeks |

| Power Surge Damage | $2,500 (AVR) | $4,000-$8,000 | 2-4 Weeks |

| Dust-Related Failure | $0 (Cleaning) | $1,500-$5,000 | 1-2 Weeks |

Cost Comparison of Prevention vs. Repair for Common Laser Cutter Issues

Conclusion: Mastering the Three Pillars of Laser Cutter Longevity

The experiences from Canada, Australia, and Africa demonstrate that while laser cutters face different challenges in different environments, the maintenance principles remain consistent: proactive prevention beats reactive repair.

By implementing these three key strategies—freeze protection for cooling systems, voltage stabilization for electronics, and regular dust management—you’re not just maintaining equipment; you’re protecting significant capital investment and ensuring production reliability.

As one Canadian manufacturer summarized after implementing these practices: “We went from constant crisis management to predictable operations. The few hours we invest in proper maintenance each month save us thousands in repairs and lost production. It’s the smartest insurance policy we’ve ever purchased.”

Your metal laser cutter is a precision instrument deserving of precision care. Through consistent, informed maintenance practices, you can maximize its lifespan, maintain cutting quality, and avoid the costly downtime that plagues so many manufacturing operations. For other precautions regarding laser cutting machines, please contact YIHAI LASER.

-

Tech1 year ago

Tech1 year agoHow to Use a Temporary Number for WhatsApp

-

Business2 years ago

Business2 years agoSepatuindonesia.com | Best Online Store in Indonesia

-

Social Media1 year ago

Social Media1 year agoThe Best Methods to Download TikTok Videos Using SnapTik

-

Technology1 year ago

Technology1 year agoTop High Paying Affiliate Programs

-

Tech9 months ago

Tech9 months agoUnderstanding thejavasea.me Leaks Aio-TLP: A Comprehensive Guide

-

FOOD11 months ago

FOOD11 months agoHow to Identify Pure Desi Ghee? Ultimate Guidelines for Purchasing Authentic Ghee Online

-

Instagram3 years ago

Instagram3 years agoFree Instagram Auto Follower Without Login

-

Instagram3 years ago

Instagram3 years agoFree Instagram Follower Without Login