Tech

Automated Storage & Retrieval System (AS/RS) Types & Uses

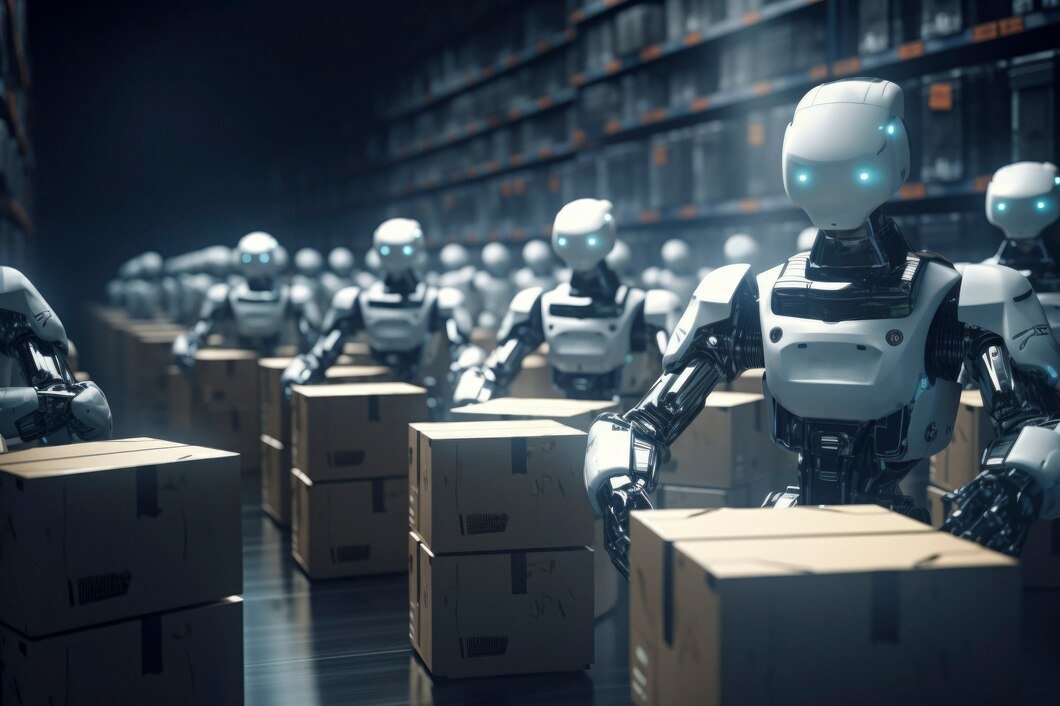

Introduction

Read through the blog to unravel the various types of automated storage and retrieval systems, their types, their industrial applications and how they enable businesses to enhance warehouse operations and improve space utilisation.

What is Automated Storage & Retrieval System (AS/RS)

ASRS solution is used in warehouses and distribution centres to autonomously place and retrieve goods from predetermined storage places, increasing efficiency and precision.

Types of ASRS & Their Uses

- Carton Shuttle – Quadron

They are designed to move commodities swiftly and efficiently from one location to another, resulting in increased production and streamlined operations. Carton shuttles can help organise products in the warehouse, making it easier for employees to find and collect items as needed.

Addverb’s innovative shuttle-based technology is equipped with vertical lifts and specialised racking, which enables high throughput and storage density. In a nutshell, it maximises order fulfilment, enhanced space utilisation, and inventory management.

How does the Quadron Work?

The Quadron-carton shuttle moves quickly through the short aisles, delivering cargo precisely to their designated spots. Its telescopic arms draw the load during recovery, ensuring smooth functioning and efficiency.

Industries Served:

- Logistics and Distribution

- Retail and E-commerce

- Healthcare

- Food and Beverage

- Pharmaceutical

- Apparel and Fashion

Benefits:

- Superior Efficiency: Quadron can aid in picking orders by transporting goods to the pick stations. This can reduce the time and effort needed for order picking while increasing production.

- Optimal Space Utilisation: Quadron can help you save storage space by arranging items compactly and efficiently. It is suitable for stacking and storing cartons in high-density storage systems.

- Enhanced Storage Capabilities: Quadron can be used for sequencing by transferring and arranging goods in a predetermined order. This can be accomplished by programming the shuttle system to follow a specific sequence when storing or retrieving products.

- Mother-Child Shuttle – Multi Pro

A mother-child pallet shuttle is an automated warehouse storage and retrieval device. It consists of a larger “mother” shuttle that moves along the aisles and a smaller “child” shuttle that runs horizontally between storage racks to deposit or retrieve pallets.

How does Multi-Pro work?

The Multi-Pro system improves warehouse automation by moving pallet loads from vertical lifts to specific storage areas.

Once the pallets have been appropriately positioned, the Cruiser, a specialised shuttle, travels to the correct location to conduct storage tasks such as slotting the pallets into their allotted slots in the racking system.

Industries Served:

- Logistics and Distribution

- Retail and E-commerce

- Manufacturing

- Food and Beverage

- Pharmaceutical

- Automotive

- Cold Storage and Refrigeration

Benefits:

- Precise pallet positioning and slotting

- Efficient pallet retrieval

- Maximising space utilisation in storage racks

- Streamlining inventory management

- Facilitates cold storage amenities

- 4-Way Pallet Shuttle – Cruiser 360

It is an automated pallet shuttle storage system which carries and stores wavy pallets in high-density racking systems, enhancing warehouse efficiency and capacity.

How does Cruiser 360 work?

- Cruiser 360 can move in different directions to transfer pallets to specific storage areas within high-density racking systems.

- It gathers pallets and transports them to the lift for further processing while responding to warehouse scalability.

Industries Served:

- Logistics and Distribution

- Retail and E-commerce

- Manufacturing

- Food and Beverage

- Pharmaceutical

- Cold Storage

Benefits:

- Precision Positioning: Servo controllers with QR code positioning allow for accurate pallet placement.

- Exceptional Storage Density: Makes optimal use of vertical space, maximising warehouse capacity.

- Unrivalled Versatility: Moves items in four directions, providing versatile storage and retrieval possibilities

- Multi-Level Shuttle – Medius

Medius is a highly dynamic multi-level shuttle system that automates the storage and retrieval of cartons/totes over many levels.

How does Medius work?

- Storage: Medius moves over numerous floors of an aisle, storing items exactly in high-density layouts.

- Retrieval: It quickly recovers products and transports them to specified pickup locations to ensure efficient order processing.

Industries Served:

- Logistics

- Consumer Goods

- Electronics

- Chemicals

Benefits:

- Superior Storage Density: Medius excels at organising items compactly and efficiently, making the best use of available space by allowing cartons to be stacked and stored in high-density systems.

- Unmatched Flexibility and Scalability: The Medius Multi-Level Shuttle provides adjustable configurations to meet various storage demands, increasing operational flexibility.

- Crane ASRS

Crane ASRS ensures correct storage by efficiently loading and unloading massive objects. It is highly adaptable and performs well in a variety of contexts. Its modular architecture, which allows pallet weights of up to 1500 kg, ensures accurate real-time inventory tracking.

How does Crane ASRS work?

- Aisle Operation: ASRS cranes employ installed rails or tracks to precisely negotiate narrow warehouse aisles, maximising storage density and vertical area usage. They are equipped with grippers, forks, or shuttles and can easily lift and transfer pallets, bins, or items.

- Automation and Integration: ASRS cranes work independently or semi-independently with computer systems such as WMS to optimise crane movements, inventory management, and storage placements based on demand.

Industries Served:

- Logistics and Distribution

- Retail and E-commerce

- Manufacturing

- Food and Beverage

- Pharmaceutical

- Automotive

- Cold Storage

- Consumer Goods

- Electronics

- Chemicals

Benefits :

- Premium Safety Standards

- Exceptional Storage Density

- Superior Versatility

6.Pallet Shuttle – Cruiser

An automated pallet shuttle storage system carries and stores pallets in high-density racking systems, increasing warehouse efficiency and capacity.

How does Cruiser work?

Cruiser glides along embedded rails to deliver pallets to their predetermined storage areas, lifting and precisely positioning them within the racking system.

The Cruiser navigates to the stated place and uses its mechanisms to retrieve and transfer the pallets to the desired position.

Industries Served:

- Automotive and Industrial Manufacturing

- Cold Storage and Refrigeration

- Consumer Goods

- Electronics and Electrical

Benefits:

- Superior Inventory Management: Improves stock level tracking and control while decreasing errors and ensuring accurate inventory counts.

- Improved operational efficiency: Simplifies warehouse operations by decreasing manual labour and increasing task completion speed.

- Exceptional Throughput: Increases the volume of items handled in a particular time frame, resulting in higher production.

- Maximised Storage Capacity: This method makes the best use of available space, resulting in improved storage density and better warehouse utilisation.

Wrapping Up

Automated Storage and Retrieval Systems (AS/RS) can improve warehouse efficiency and organisation. Choosing the correct AS/RS type might help you streamline your processes and reduce costs. Investing in this technology can increase your productivity and provide a competitive advantage.

Partner with us to leverage cutting-edge robotics and automation solutions that transform supply chains and elevate operational efficiency.

-

Business10 months ago

Business10 months agoSepatuindonesia.com | Best Online Store in Indonesia

-

Technology6 months ago

Technology6 months agoTop High Paying Affiliate Programs

-

Tech3 weeks ago

Tech3 weeks agoUnderstanding thejavasea.me Leaks Aio-TLP: A Comprehensive Guide

-

Technology2 months ago

Technology2 months agoLeverage Background Removal Tools to Create Eye-catching Videos

-

Tech10 months ago

Tech10 months agoAutomating Your Window Treatments: The Advantages of Auto Blinds

-

Tech10 months ago

Tech10 months agoUnleash Your Potential: How Mecha Headsets Improve Productivity and Focus

-

Instagram2 years ago

Instagram2 years agoFree Instagram Follower Without Login

-

Instagram2 years ago

Instagram2 years agoFree Instagram Auto Follower Without Login